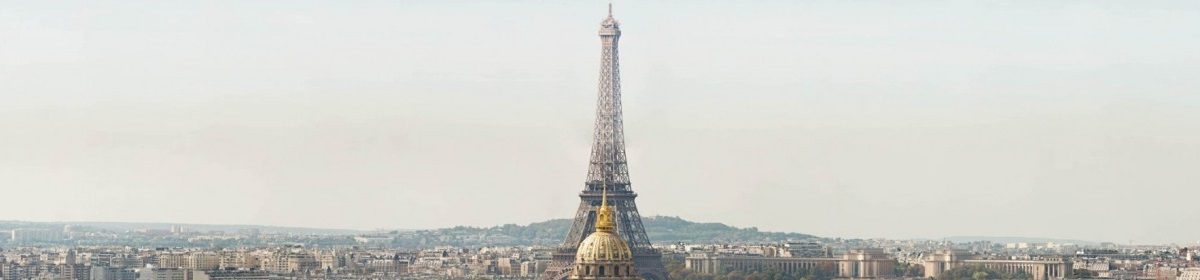

It was a good day, but a long day. It is 11pm and we are just getting back to the hotel after seeing versailles, enjoying a French dinner, learning the subway, and visiting Sacre Coeur. We will post pictures tomorrow. We are all well and things are quiet where we have been.

Month: January 2019

Burke Porter Company Visit

Yesterday, our group had the privilege of visiting Burke Porter Company while in Brugge. Burke Porter is a conglomeration of multiple companies which together produce innovative products in advanced manufacturing, advanced vehicle testing, and life science sectors. Today, their company has locations in 31 locations across 4 continents. The facility in Brugge is the location of the BEP Europe headquarters.

This was the first time I had heard of Burke Porter Company. I was amazed to see their wide range of products. With having past experience working in brake systems, I enjoyed most hearing about their vehicles testing technology. This is an entire market I often forget about. We not only need products as consumers; these products often need validation testing that require equipment of their own.

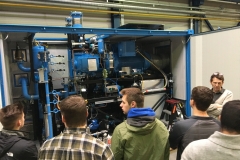

What I enjoyed most about this company tour was how interactive our visit was. The salesman which showed us around allowed us to get up and close with the technology. We got to walk on to their wheel alignment machine which can align wheels within minutes compared to what you experience at a standard car garage. He also handed us sensors to inspect. Most explanations about their products was often followed by a cool demonstration.

A difference between the European work culture and the American work culture that we discussed were salaries. The salesman talking to us was surprised to hear that there is about a $10k difference in starting pay for engineers. This ironic since life in Europe is more costly. I also appreciate the European’s ability and desire to learn multiple languages. With their ability to travel easily from country to country, knowing how to speak the native language of the people you sell to makes all the difference in business.

As a future employee, I appreciated the salesman’s emphasis on knowing everything about what you’re selling. He’s a business man by trade, but has the technological knowledge of those who created the products. He repeated to us to always be well prepared and never make empty promises to your customers. I learned a lot from this tour and look forward to what’s next.

Day 5 – Burke Porter Europe and Bruges

It’s the little things

There are a few cultural differences that you wouldn’t think would prove to have a larger impact overtime. On one end, there are a few annoyances such as paying for water or paying to use the restroom. There’s never an outlet next to my bed to charge my phone and lets me honest the wifi is constantly kicking you off. On the other hand, I have found the european culture to be quite refreshing. I have loved the idea of public transportation or even the lifestyle of walking/biking to every place you go. What a great way to stay healthy but also care for the environment. I have also enjoyed the longer meals europeans share with one another. It has been a blessing to sit down for dinner and not rush it, but rather enjoy the company at my table whether that be my best friends or other students on the trip that I have gotten the opportunity to get to know. This “slower pace” seems to translate into the business world as well – people often taking breaks for coffee with one another. Another plus is not having to share a bed but still getting to sleep next to your best friend. That’s the “best of both worlds sleepover” if you ask me. All in all, I have enjoyed all the experiences I have had in Europe, but it will be the little things that I will cherish for a lifetime.

Vermeer Manufacturing

Vermeer Manufacturing all started in Pella Iowa when Gary Vermeer was looking for more efficient ways to do the most basic farming tasks as opposed to the old ways of his ancestors. In 1948, Gary started Vermeer Manufacturing and launched a variety of products, but it wasn’t until 1971 that his business really launched when his team invented a new way of baling hay. Ever since, they’ve been creating machines and products for 60 countries to fuel and feed their communities.

We had the opportunity to visit one of the regional facilities in the Netherlands. We met with Baaker, the operational financial officer, who gave us his take on the company he has been with for nearly 22 years. After speaking with Baaker as well as other engineers and manufacturers in the building, we have a few takeaways from the day.

First, Baaker describes the differences in the “business culture” in American from Europe after living there with his family for two years. He noted the struggles of working with a team in Pella, Iowa. Though America may not have as much of a hierarchy as Germany or Italy, Baaker found it extremely difficult to receive honesty and build trust with his subordinates. They would prefer to take direction as opposed to working as a team and challenging one another. This is very different from the European business culture where the hierarchical lines blur together and where colleges are not afraid to be blunt with one another.

Another take away we gathered from the tour was the struggles that occur from having an international company. Vermeer pointed out two main aspects that need to be considered – who is manufacturing the products and who are the customers. This particularly matters because countries have different measuring systems (ie. imperial vs. metric system). Depending on where the product is being made directly impacts the plans for the manufacturers and moving the production requires the plans to be converted. Secondly, the manufacturers need to be aware of their customers and what the regulations and restrictions are in the country they reside. For example, europeans require tighter restrictions on those who can tow trailers as well as what the weight of the trailers can be.

Our last take away, and the one I found to be the most fascinating, is the importance of data analytics. Baaker could not have stressed this topic more. He used the analogy of literacy. In the middle ages not everyone was literate and only the monks and others could read it write, giving them a great advantage. This same idea goes for businesses and their data analytics. Those that can not only gather data, but also interpret it are those that can be the most innovative and move their company and even industry forward.

Burke Porter Group

Today we visited the Burke Porter Group in Brugge, Belgium. This company was founded in Grand Rapids, MI more than 60 years ago as a manufacturer of large machines. Today, the Burke Porter Group has aquired lots of different types of companies in an effort to diversify their buisiness.

The building we toured deals specifically with making large machines for “end of line” testing for cars. These machines test things like braking system and autonomous driving systems for major car companies.

Upon our visit, we were first given an extensive summary of how the buisiness has evolved over the years and details of the many different end of line testing systems that were made in the facilities. Then, we were taken for a tour of the facilities to get a more hands-on idea of the production of these machines. It was very interesting to see how they create the same testing machines in slightly different variations in order to satisfy different customer needs.

Burke Porter is a solid company that has worked extensively to diversify in order to succeed. They push the boundaries in various fields and have profited greatly from a hard working mentality. It was a pleasure touring their facilities and learning from them.

Vermeer

We started the day off with a tour at Vermeer. It wasn’t as much of a tour as it was an informational session with Jaap. He was very impressive; he was in operations, finance, and IT throughout his career, and from my understanding, did well in each area. He loves data and making data relevant to make decisions.

Vermeer started with Gary Vermeer. He was a farmer and had an extreme passion for farming and advancing tactics. He hated having to bail hay, and ended up creating a successful prototype that would bail hay in the big circles instead of smaller rectangles. By doing this, you could leave the hay out and the rain would not ruin it, unlike the rectangular bails. His neighbors saw what he had created and they wanted a machine as well. So, he ended up creating these machines for them and realized that he was a manufacturer.

He and his newfound company never looked back. They started making items such as woodchippers, directional drills, stump cutters and so forth. He was a very innovative man, and his company grew tremendously as a result. They currently (according to Jaap) have a net worth of a little over a billion dollars. They have plants in Iowa, China, Latin America, the Netherlands, and Asia Specific. So, they are a very large and innovative company, who continues to have success.

Vermeer corp

We visited the Vermeer corporation on Tuesday. I was interested in this visit because the company is actually headquarters in Iowa. Which was funny since that is so close to Michigan and here we are in the Netherlands visiting the company.

I enjoyed learning about how they manufacture their farming and outdoor tools. The facility is the Netherlands was not a manufacturing facility orgibally. But due to a tornado that struck in the United States, this facility was quickly transformed into a manufacturing facility in order to keep up with demand and fulfill order.

It was interesting to watch them assemble the machines as we stood there and spoke with some of the workers and engineers.

Vermeer prides itself on being ahead of the safety curve so to speak. They implement safety features into thief machines before safety regulations are placed on them so they always have the safest machines. Where as competitors wait until the safety regulations are released before making thief machines more safe.

Overall Vermeer was very interesting and a exciting place to visit. They also gave us delicious pastries at the end, always a plus.

Maeslantkering- Day 3

The Maeslantkering is a storm surge barrier on the Nieuwe Watereg, in South Holland, Netherlands. It is controlled by a supercomputer, and automatically closes when Rotterdam is threatened by floods. It is one of largest moving structures on Earth. The main purpose of this barrier is not to control the water, but rather to slow the waves/break the force of the waves.

There are two large floating gates on both dikes of the waterway. The construction of these dikes started in 1991 and it took six years to build the 22 meter high and 210 meter long steel gates. Due to the size of these gates, they take two hours to close. Although they are only expected to need to be closed once every ten years, they are very worth it. The efficiency of them to prevent catastrophic flooding is vital to the Netherlands. Without the barriers, mass destruction and death could occur.

The Netherlands also employ natural tactics to help prevent flooding. An example of this is deploying sand a decent way into shore and using this sand to ease the waves and to help lead to dunes being created. The dunes will act as natural barriers to the threatening waters. Another cool fact is that the storm surge barriers are painted white in order to reflect the sun so that they don’t contract due to the heat.

Day 4 – Vermeer, Veere, Middleburg, Bruges

We saw a different type of storm surge barrier. There was a brisk wind coming off the North Sea.

On to Veere a beautiful village that booms in the summer as a vacation and boating destination

Got to our hotel in Bruges in time for a quick night tour of the lighted city.

Then, a nice steak dinner in an old-town resturant